Veneering

Veneer technology was developed around 3000 BC in Egypt but the heyday of veneers transpired during renaissance, baroque and rococo. Today, Cabinet makers produce complex veneer surfaces.

Application is where most of the difference is made.

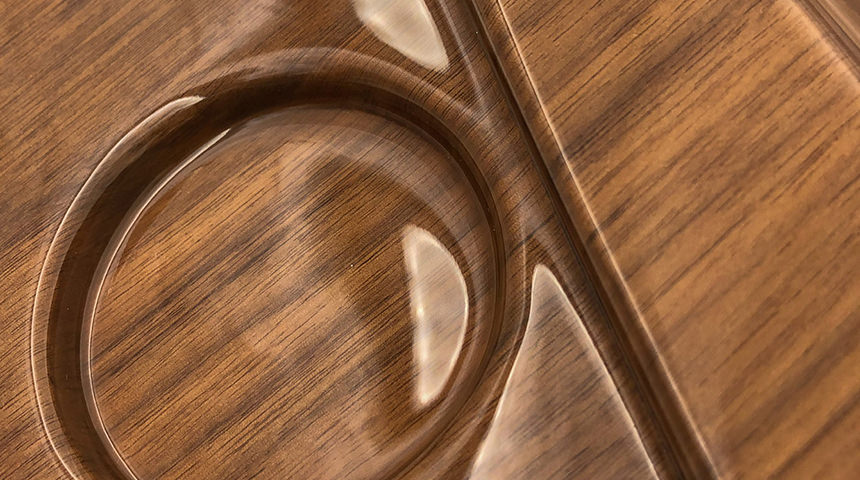

We believe in seamlessness. From single narrow plies, we strive to create complex and expansive surfaces in which the split line is concealed, thereby resulting in a wood pattern that exhibits perfect continuity and harmony.

The Process

Projects

In the hands of an expert, veneering technique can produce some of the most remarkable effects in woodworking. This goal is only obtained through our extensive knowledge of the raw material that we work with, enabling an intimate understanding of the interactions between the curves and edges of the artifacts, a process that brings out the best of what the material has to offer.

The idea behind the DTales project is to combine the expertise of our master craftsmen with the study and use of innovative technologies to create exquisitely tasteful pieces that overwhelm the onlooker with emotion.

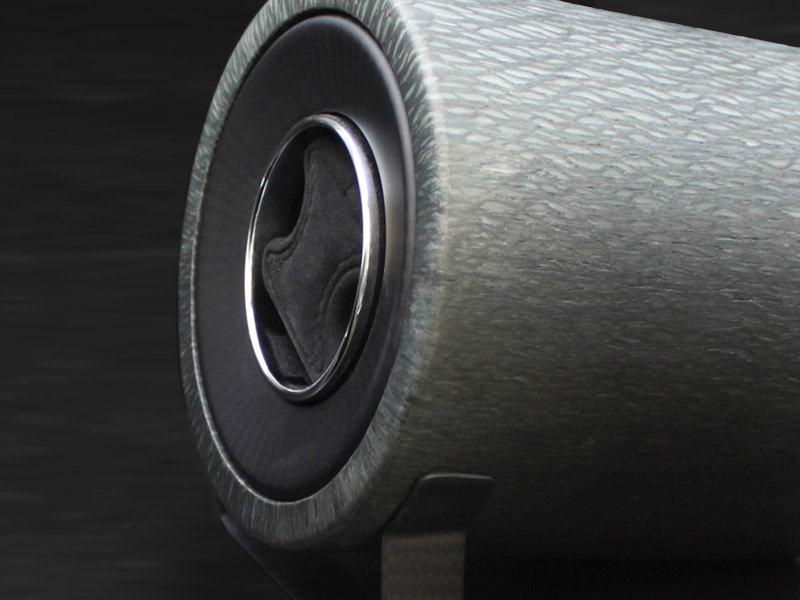

Our expertise extends to decorative coverings in composite materials such as carbon fibre.